1、 Product Introduction of LZX10 Weighing Sensor by American Zhongkesel Brand

Product brand:Axel in the United States ZXSCELL

Product series: LZX10

Product type:Single point weighing sensor

Product range: 3kg, 6kg, 10kg, 20kg, 30kg, 35kg, 50kg

Product Introduction

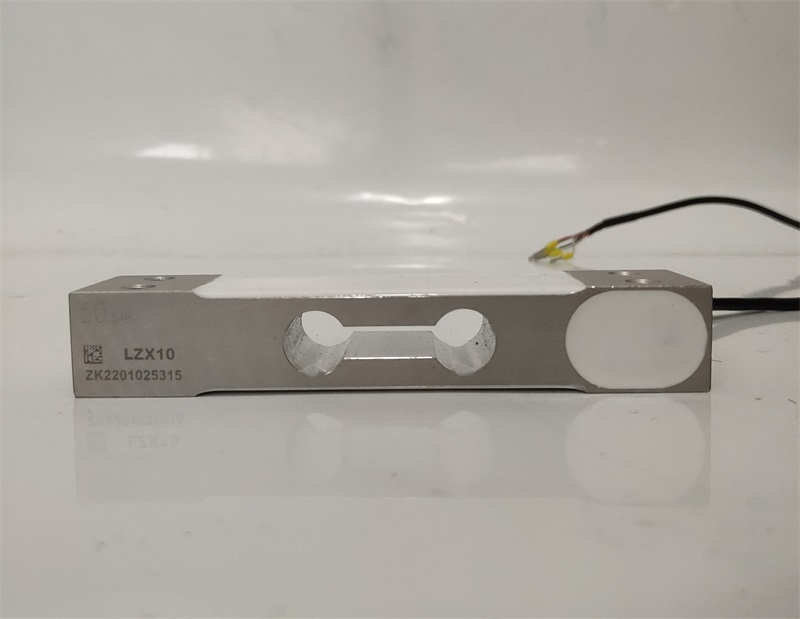

(1) The LZX10 model belongs to the single point weighing sensor, with a rated range ranging from 3kg to 50kg and a C3 accuracy level. The cable adopts four core shielded wire.

(2) The material of LZX10 sensor is aluminum alloy, and the surface of the sensor is sealed with silicone rubber technology.

Product Features:

(1) Aluminum alloy material, nickel plated coating

(2) Surface silicone rubber sealing process

(3) Four core shielded wire

Product application:

(1) Packaging scale

(2) Electronic platform scale

(3) Small hopper scale

(4) Ingredient system

2、 Image of LZX10 weighing sensor from the American brand Zhongkesel

3、 LZX10 weighing sensor product model

LZX10-3kg

LZX10-6kg

LZX10-10kg

LZX10-20kg

LZX10-30kg

LZX10-35kg

LZX10-50kg

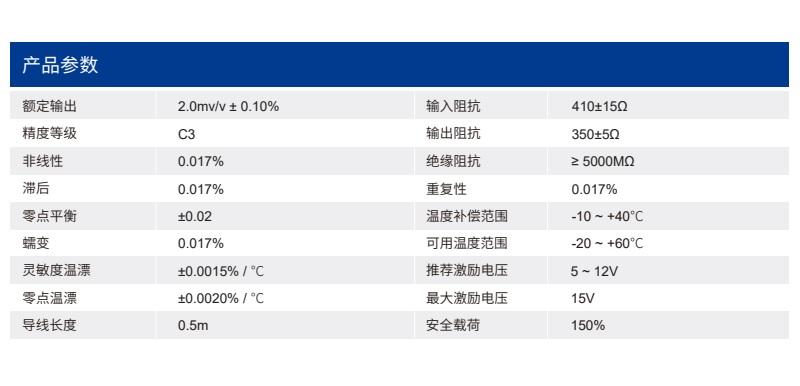

4、 Technical parameters of LZX10 weighing sensor

Sales contact information:

Miss Chen:

sales@zhongxintmt.com

Mr. Huang:

huanghao@zhongxintmt.com